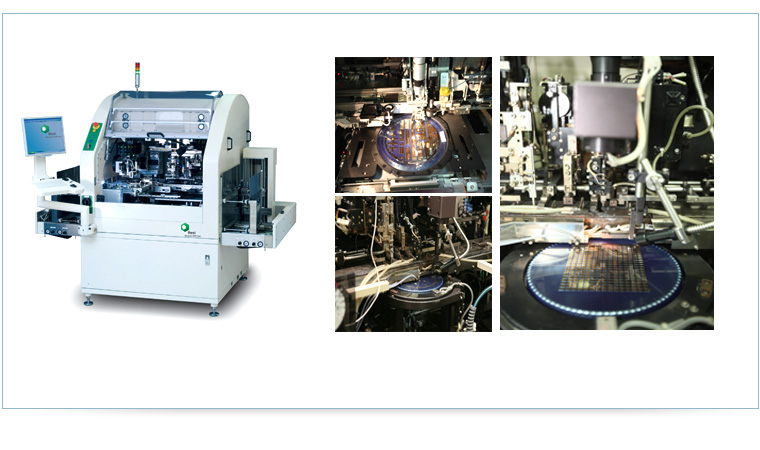

Die Bonding

• Process contentThe process of attaching a semiconductor chip to a substrate or die pad using epoxy or solder as a semiconductor component assembly technology

| Main features | Production capacity | |

|---|---|---|

| Die bonder | Epoxy die bonder | UPH : 600EA/Hr (UPH : Unit per Hour, production quantity per hour) |

| Solder bonding method : How to connect with lead and tin-based solder | Resin adhesion method : How to use an adhesive such as an epoxy-based resin containing silver or a polyimide-based resin containing silver | |

Wire Bonding

• Process contentThe process of connecting a semiconductor chip and a lead electrode with very fine high purity gold or aluminum, copper, etc.

| Main features | Production capacity | |

|---|---|---|

| ·ALC(Active Loop Control) bond head provides Front and Rear type · High resolution encoder measures wire strain with precision(0.5㎛) · High resolution encoder measures wire strain with precision(0.5㎛) |

UPH : 720EA/Hr | |

Ceramic Substrate Print

• Process contentProcess to make a single electrical circuit board by repeatedly printing and drying and baking various paste materials such as resistors, conductors, and protective films on ceramic substrates

| Main features | Production capacity | |

|---|---|---|

| ·Semi auto process for high temperature firing at 500 and 850 degrees · Print resistance with thickness less than 20㎛ · Realization of high integrated circuit through the use of AL(alumina) substrate with excellent heat dissipation properties |

UPH : 2,000EA/Hr | |

Laser Passive Triming

• Process contentProcess for laser-correcting the resistance of the printed ceramic substrate

| Main features | Production capacity | |

|---|---|---|

| The desired resistance value is automatically corrected using an automatic laser, and an automatic inspection function for the corrected value is possible. | UPH : 2,000EA/Hr | |

Auto Assembly Line

• Process contentArray A process that automatically performs a series of assembly processes such as Dividing / Seating / Coating silicon in an array state / Laser welding / Equipment assembly / Screw fastening / Hardening / Test

| Main features | Production capacity | |

|---|---|---|

| Auto Assembly Line

- Building on the basis of Laser Welding Assembly method and 100% automatic assembly line through pellet transportation and logistics automation. |

UPH : 250EA/Hr | |

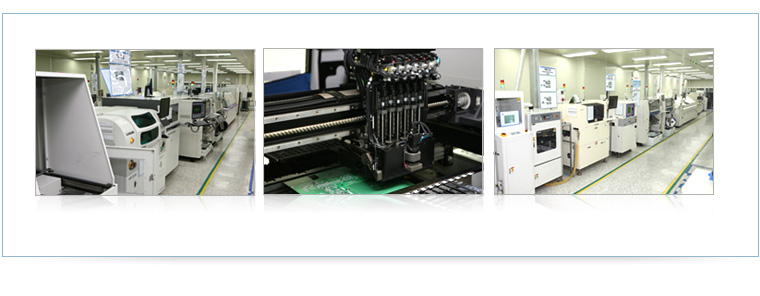

SMT(Surface Mounter Technology)

• Process contentProcess of mounting and soldering surface-mounted components on the surface of an electronic circuit board

| Main features | Production capacity | |

|---|---|---|

| ·Build traceability system through lot marking of all products ·Screen printer with humidity control function ·100% solder printing inspection by applying 3D SPI IN-LINE ·Reel Swap Error Protect System applied ·Securing soldering quality by applying nitrogen reflow ·3D AOI IN-LINE application and secured lifting power of parts ·On-site cleanliness management by building air-shower room |

- MOUNTER CPH - ·CHIP only : 80,000CPH ·Variant only : 30,000CPH (CPH : Chip per Hour) |

|

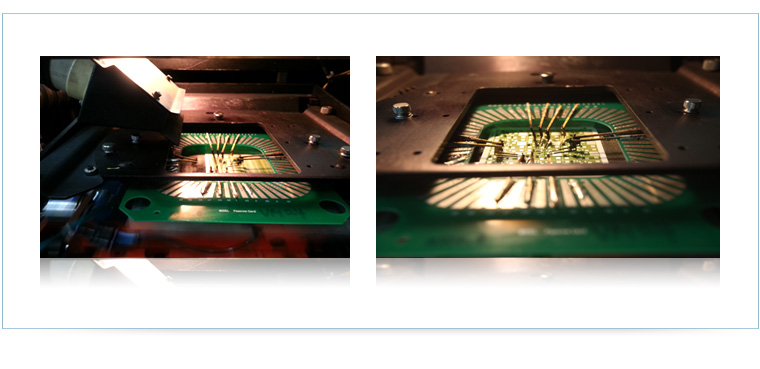

Terminal Pin Insert Process

• Process contentProcess of automatically inserting terminal pin into PCB hole

| Main features | Production capacity | |

|---|---|---|

| · Vision : Automatic optical position control · 3 head change applicable · Custom tooling production available ·Quick model change by applying tool change kit |

UPH : 400EA/Hr (8-pin criterion) | |

Conformal Coating Process

• Process contentThe process of coating a coating film to prevent insulation, damage and corrosion of components mounted on the substrate

| Main features | Production capacity | |

|---|---|---|

| · Can be changed to spray nozzle dispenser · Spray, film and dot application methods are all applicable |

UPH : 360EA/Hr | |

Function Test

• Process contentThe process of making good and bad judgment by measuring performance to increase the reliability of the product

| Main features | Production capacity | |

|---|---|---|

| ·Function Test : 100% Total inspection(Inspect only products with good performance in the previous process) ·Test method : 100% Automatic inspection ·Test temperature : Hot & Room Test (High temperature unapplied products : Aging test in progress) ·Test Data : 100% auto savebr/> ·Defect isolation : Blocking of mixing through automatic defect isolation |

UPH : 200EA/Hr(More than 5,000k/year) | |

In Circuit Test

• Process contentAfter completing the SMT process, the process of inspecting the electrical characteristics such as the open/short state of the board circuit

| Main features | Production capacity | |

|---|---|---|

| ·In Circuit Test : 100% Total inspection(Only products with good quality in the previous process are inspected) ·Test method : 100% Automatic inspection ·TTest Data : 100% Auto save ·Defect isolation : Blocking of mixing through automatic defect isolation |

UPH : 200EA/Hr(More than 8,000k/year) | |